If you’re researching membrane switches, have you found a number of product options with a dizzying array of naming conventions? Use the following membrane switch reference guide to cut through the clutter – and identify the right solution for your project.

Types of membrane switches

|

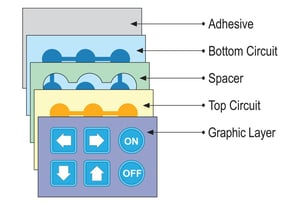

Non-tactile membrane switch

|

This switch is called “non-tactile” because it does not give direct feedback to the user. However, other types of feedback can be added such as a sound beeper, LED indicator, or display change. Advantages of this type of switch – The non-tactile membrane switch is a reliable, economic choice. Additionally, it’s easy to create custom shapes and sizes of the active keypad area. Material and construction notes – This flexible membrane switch consists of layers of polyester printed with a conductive silver ink. How it works – The switch action is SPST-NO (single-pole, single-throw, normal-open), created by placing a spacer layer between two layers of conductive silver ink. This creates a gap that, when pressed, bridges the two layers and closes the contacts. The top circuit carries one layer of printed silver ink, which connects to one of the terminations on the switch tail. The bottom circuit has a second layer generally connected to a ground or common pin.

|

|

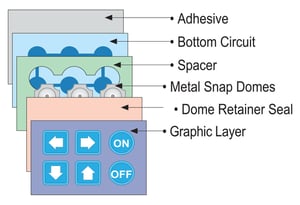

Tactile membrane switch (aka metal dome or polydome membrane switch)

|

This switch features a snap action that is clearly noticeable to the user. Conductive metal domes have the best action and can eliminate the need for a flexible upper circuit layer. Material and construction notes – The snap acting contact dome can be a nickel-, silver- or gold-plated stainless steel spring, placed between the top and bottom circuit switch openings. Choose metal or polydome – The distinct snap or click feel (and sometimes sound) of the metal dome gives direct feedback to the user. Formed polydomes offer a milder tactile response. Note: Polydomes have a narrower operating temperature than the metal dome.

|

|

Mixed panel membrane switch

|

Non-tactile and tactile switches can be mixed in the same panel. This can be desirable when a large active area is needed for a particular switch.

|

|

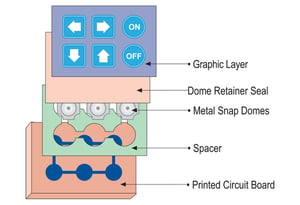

Rigid membrane switch (aka PCB-backed membrane switch)

|

A printed circuit board (PCB) can be used for the lower circuit, while providing structural support. Material and construction notes – The rigid membrane switch generally consists of one switch layer of polyester printed with conductive silver ink. The second contact surface is a conductive circuit of etched plated copper encased in a PCB encapsulated with an epoxy insulating material and protected with a dielectric layer. The PCB provides a rigid support that can be used to mount the switch circuit to a housing or backing plate. Choose non-tactile or tactile – Rigid membrane switches can be non-tactile by incorporating a printed silver contact method with a spacer layer in between. They can be tactile by incorporating the snap acting contact dome.

|

|

Flex circuit membrane switch (aka flexible circuit membrane switch)

|

Ideal for harsh environments, this switch is an etched copper circuit lead-frame encased in a Kapton or polyimide material. The flex circuit membrane switch offers many of the benefits of a rigid (PCB-backed) membrane switch, plus it can be combined with the lower-cost options of a non-tactile or tactile membrane switch assembly.

|

Watch for common pitfalls – follow these recommendations for success

As you may know, membrane switch design and fabrication involves extensive choices and decisions in order to meet exacting specifications. The design and engineering team you choose will guide you to meet your goals regarding dimensions, quantity, budget, and project due date while considering the environment, durability, usability, and mounting.

The nearly overwhelming decisions include choosing overlay materials, domes and actuation, design and construction materials, circuitry and shielding, venting between assembly layers, feature locations, connector tails, colors, lighting, sub-panels, and more. Look to an experienced membrane switch company that will team with you – and actively communicate with you – to finalize all specs. That’s why it’s vital to select an established, US-based company backed by years of experience versus a new-to-market manufacturer that may be located offshore and may lack experience.

When selecting a membrane switch manufacturer, ask these questions:

- Experience – How long has the company been designing and manufacturing switches? Do they offer a depth of experience or are they new to market?

- Expertise – Does the company have in-house designers and engineers? Will they actively team with you, guiding you to choose the type of membrane switch and materials that meet your project needs?

- Quality – Is the company ISO-certified?

- Communication – Will the communication be clear and consistent? (Language issues can be extremely challenging and, worse, miscommunications can endanger your project’s delivery date.)

- Rapid prototyping – Does the company offer quick-turn prototyping to support an innovative design process?

- Total lead time required – How much time is required for design, manufacturing, and delivery?

Follow these recommendations for your membrane switch design:

- Use non-tactile keys for maximum reliability and when fast data entry is required. Use tactile keys for discrete operation

- A .10-inch minimum between any 2 active areas should be allowed

- Keypad graphics can be .20-inches larger than the active switch area

- All switches should be at least .25-inches from a panel edge

- Group switches with similar functions together by color or location

- Avoid positioning more active switches in potentially awkward locations

- Avoid obscuring a display when a switch is operated

Get this Membrane Switch Design Guide – and get started

Complete the form below to get your FREE, in-depth Membrane Switch Design Guide.