In the heart of industrial manufacturing, efficiency, reliability, and precision are not just goals—they are imperatives. This is where Design Mark, a leader in custom-engineered solutions, steps in with its advanced membrane switches, transforming the way industries operate. Membrane switches, often overlooked, play a pivotal role in ensuring the seamless function of machinery and equipment across various sectors. This blog explores the significance of membrane switches in industrial manufacturing and how Design Mark is at the forefront of this technology.

In the heart of industrial manufacturing, efficiency, reliability, and precision are not just goals—they are imperatives. This is where Design Mark, a leader in custom-engineered solutions, steps in with its advanced membrane switches, transforming the way industries operate. Membrane switches, often overlooked, play a pivotal role in ensuring the seamless function of machinery and equipment across various sectors. This blog explores the significance of membrane switches in industrial manufacturing and how Design Mark is at the forefront of this technology.

Understanding Membrane Switches

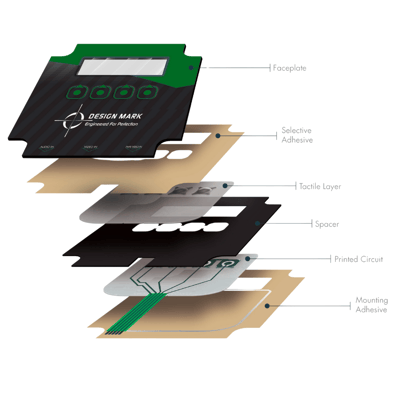

Membrane switches are user-interface controls that activate functions within machinery or equipment. Unlike traditional mechanical switches, they are made from soft materials, such as thin layers of plastic or silicone. These switches are not only versatile but also durable and cost-effective, making them an ideal choice for industrial applications.

The construction of a membrane switch includes several layers, which comprise the graphic overlay, the dome switch or flat switch layer, the circuitry, and the adhesive backing. This design allows for the creation of a wide range of tactile responses, custom shapes, sizes, and functionalities tailored to specific applications.

Advantages of Membrane Switches in Industrial Manufacturing

- Durability and Reliability

Industrial environments are often harsh, with exposure to dust, liquids, and continuous mechanical wear. Design Mark’s membrane switches are designed to withstand these conditions, offering superior durability and reliability. With their ability to resist environmental factors, these switches ensure that machinery continues to operate efficiently, minimizing downtime and maintenance costs.

- Customization and Integration

One of the standout features of Design Mark’s membrane switches is their high level of customization. They can be engineered to fit any application, with custom graphics, shapes, and sizes. Additionally, they can incorporate various functionalities, such as LED indicators, backlighting, and even touch screens, making them highly versatile. This customization extends to the integration with existing machinery, ensuring a seamless operation and user experience.

- User-Friendly Interfaces

In industrial settings, the clarity and ease of use of control interfaces are crucial. Membrane switches offer a user-friendly interface, with clear labeling and intuitive designs that reduce errors and improve efficiency. The tactile feedback provided by these switches also ensures that operators can confidently use machinery without the need for constant visual confirmation.

- Cost-Effectiveness

Despite their advanced features and benefits, membrane switches are a cost-effective solution for industrial manufacturing. Their durability reduces the need for frequent replacements, while their efficiency and reliability contribute to minimizing operational costs. Additionally, the ability to customize these switches according to specific needs ensures that companies only pay for what they truly need, without compromising on quality or functionality.

Design Mark’s Commitment to Innovation

Design Mark stands out in the industry for its commitment to innovation and quality. With over 40 years of experience, the company has continuously evolved its product offerings to meet the changing needs of the industrial manufacturing industry. Design Mark’s membrane switches are not just products; they are solutions designed to enhance efficiency, reliability, and user experience.